Sales Hotline:

+8618365715813

Sales Hotline:

+8618365715813

Product Description

Hot dip galvanized steel pipe has the advantages of strong corrosion resistance, not easy to rust, long life, relatively cheap price, etc..Hot dip galvanized steel pipe is more widely used in greenhouse.

Galvanizing can increase the corrosion resistance of steel pipe and prolong its service life. Galvanized Pipe USES is very wide, in addition to a general low pressure fluid such as water, gas, oil line pipe, also used as oil industry, especially the ocean oil field oil well pipe, oil pipe, chemical coking equipment of oil heater, the condensing, exchange of coal distillation wash oil cooler for tube, and trestle pile, mining tunnel supporting frame tube, etc.

Product Specification

|

Standard

|

AiSi, ASTM, bs, DIN, GB, JIS

|

|

Grade

|

SPCC,SPCD,SPCE,ST12-15,DC01-06,Q195A-Q235A,Q195AF-Q235AF,

Q295A(B)-Q345A(B) |

|

Type

|

Pre-galvanized pipe/Hot dipped Galvaniezd Pipe/ERW Steel Pipe

|

|

Type of coating

|

Galvanized

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching

|

|

Thickness

|

0.5-20mm,as required by you

|

|

MOQ

|

1 Ton

|

|

Payment

|

30%TT for deposit, 70% balance before shipment

|

|

Delivery time

|

8-14 days after deposit

|

Get a free quote or free sample

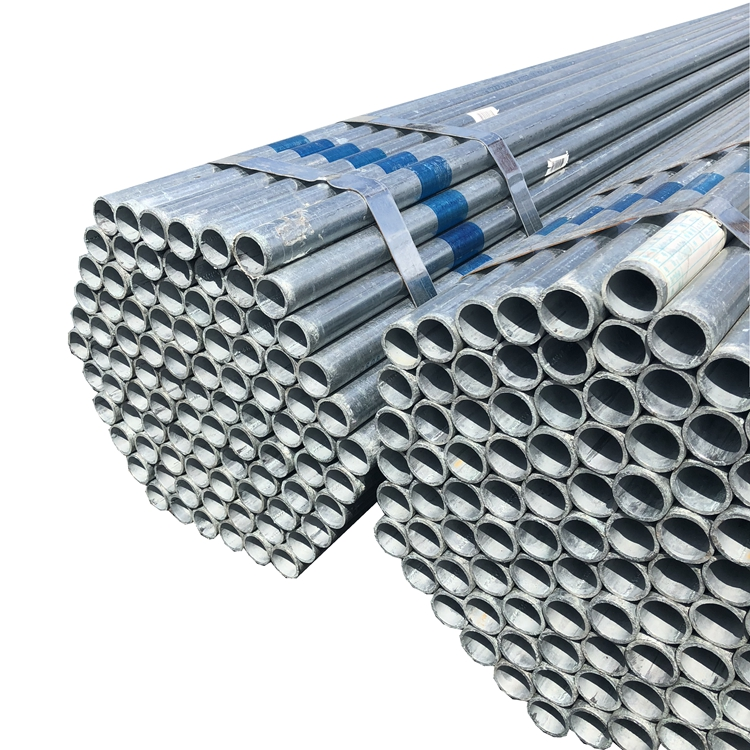

Product Display

Product Application

4.agricultural machinery, petroleum machinery, prospecting machinery, greenhouse construction, etc. industry.

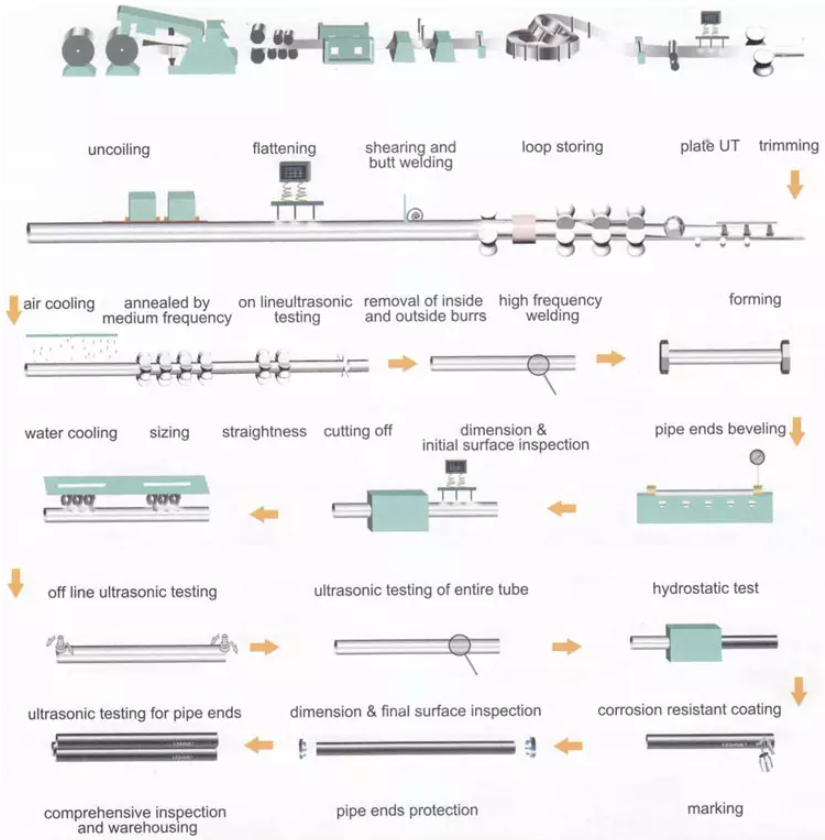

Production Process

Our Certifications

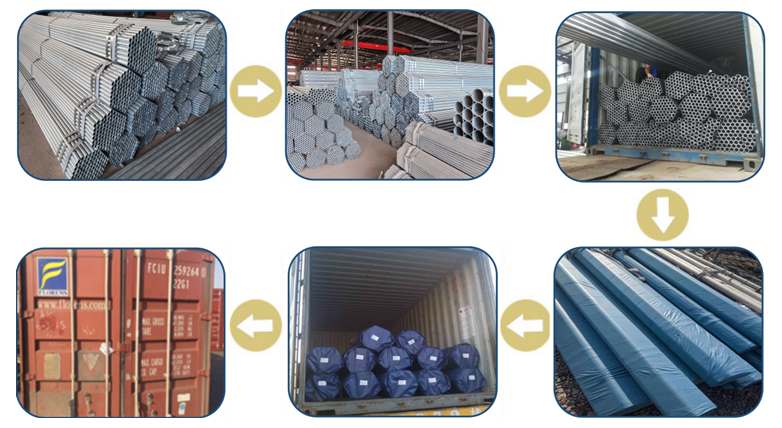

Packing & Delivery