Sales Hotline:

+8618365715813

Sales Hotline:

+8618365715813

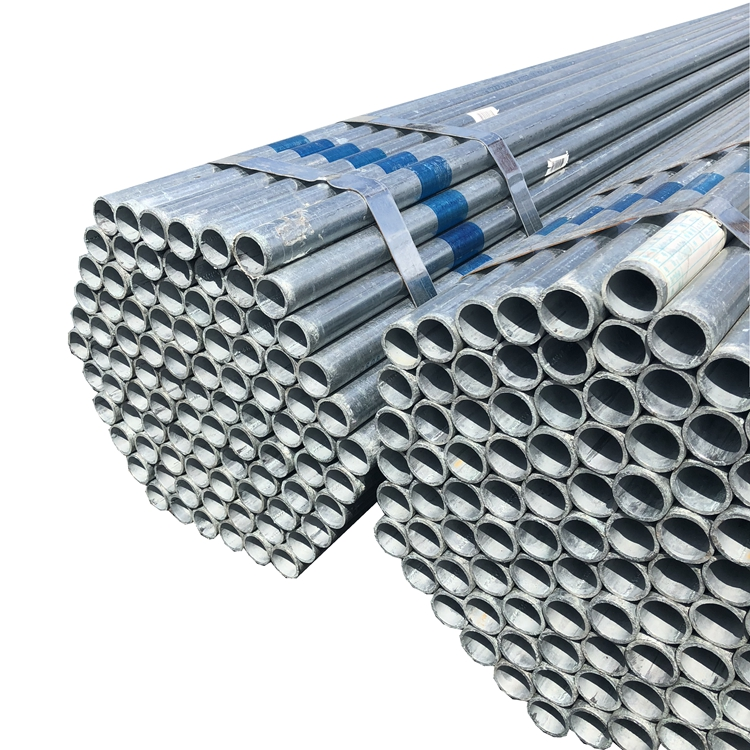

Product Description

Hot dip galvanized Steel Pipe is to make molten metal and iron matrix reaction and produce alloy layer, so that the matrix and the coating of the combination of the two. Hot dip galvanized steel pipe is first pickling steel pipe, through ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank for cleaning, and then into the hot dip plating tank. Connection mode: threaded, welded.Hot dip galvanized steel pipe has the advantages of strong corrosion resistance, not easy to rust, long life, relatively cheap price, etc..Hot dip galvanized steel pipe is more widely used in greenhouse.

Galvanizing can increase the corrosion resistance of steel pipe and prolong its service life. Galvanized Pipe USES is very wide, in addition to a general low pressure fluid such as water, gas, oil line pipe, also used as oil industry, especially the ocean oil field oil well pipe, oil pipe, chemical coking equipment of oil heater, the condensing, exchange of coal distillation wash oil cooler for tube, and trestle pile, mining tunnel supporting frame tube, etc.

Product Specification

|

Commodity Name |

Welded Hot Dip Galvanized Steel Pipe |

|

Material |

ASTM A252B, ASTM A53B, API 5L Gr.B,ST52, ST37,ST44 SAE1010,S45C ,SCM435,AISI4130 |

|

Tolerance |

Outer Diameter:±0.3mm Wall Thickness:±0.05mm Length:±6mm |

|

Chemical Composition |

C:≤0.25

Mn:≤0.95 P:≤0.05 S:≤0.06 Cu:≤0.40 Ni:≤0.40 Mo:≤0.15 Cr:≤0.40 V:≤0.08 |

|

Mechanical Properties |

Tensile strength (σb):≥330 Yield point (σs):≥205 |

|

Ends |

Plain end Beveled,Protected by Plastic Caps on Both Ends, Cut Quare,Grooved,Threaded and Coupling,etc. |

|

Application |

1.construction, machinery, coal mine, chemical industry, electric power

|

|

Packaging |

Standard Export Packing,Bundle, or With All Kinds of Colors PVC or as Your Requirements |

|

Delivery Time |

Within 14 Days after Receiving 30% TT Advanced or LC at Sight Original |

Get a free quote or free sample

Product Display

Product Application

4.agricultural machinery, petroleum machinery, prospecting machinery, greenhouse construction, etc. industry.

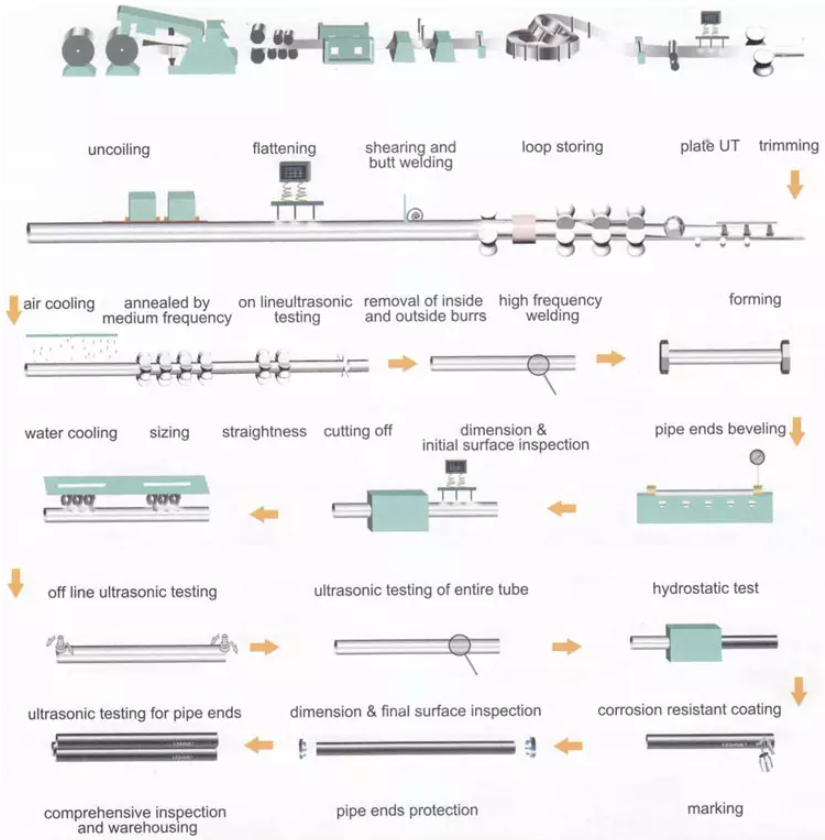

Production Process

Uncoiling →Flattening →Shearing and Butt Welding →Loop Storing →Forming →High Frequency Welding →Removal of Inside and Outside Burrs→on Lineultrasonic Testing→Annealed by Medium Frequency →Air Cooling and Water Cooling →Sizing → Straightness →Cutting off →Dimension and Initial Surface Inspection→Pipe Ends Beveling → Hydrostatic Test → Ultrasonic Testing of Entire Tube→ off Line Ultrasonic Testing→Ultrasonic Testing for Pipe Endsultrasonic Testing→Dimension and Final Surface Inspection→Corrosion Resistant Coating→Marking→Pipe Ends Protection→Comprehensive Inspection and Warehousing

Our Certifications

Our Certifications

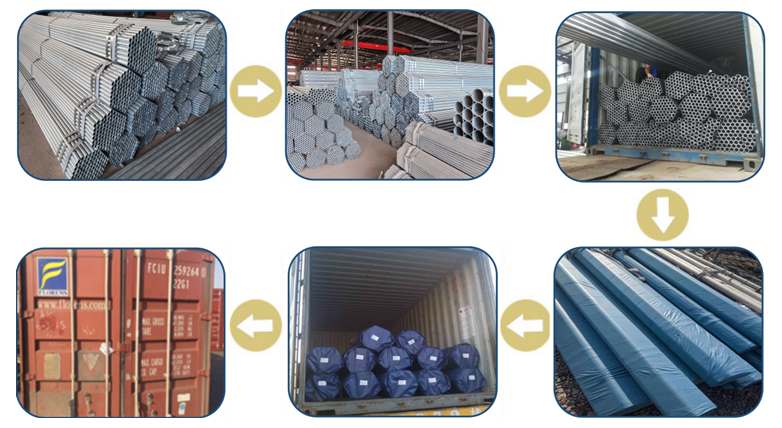

Packing & Delivery

Packing & Delivery