Sales Hotline:

+8618365715813

Sales Hotline:

+8618365715813

Product Description

The pressure resistance of Ductile Iron Pipe is more than 3MPa, the pipe diameter is 80 ~ 2000mm, and the effective length is 4 ~ 6m. It has the corrosion resistance of cast iron pipe and the toughness and strength of Steel Pipe, and has the advantages of impact resistance, vibration resistance, thin pipe wall, etc., and is widely used in urban water supply, drainage and gas transmission projects. The production method of ductile iron pipe is to add magnesium or rare earth magnesium alloy spheroidizing agent to hot metal before pouring to spheroidize graphite, and add a certain amount of ferrosilicon or calcium silicon alloy as inoculant to promote the precipitation of graphite spheroidize

Product Specification

|

Min. Thickness of pipe (µm)

|

Min. Thickness of inside joint (touch water) (µm)

|

Min. Thickness of inside joint (no touch water) (µm)

|

|

900

|

250

|

150

|

|

|

||

|

Min. Thickness of pipe (µm)

|

Min. Thickness of inside joint (touch water) (µm)

|

Min. Thickness of inside joint (no touch water) (µm)

|

|

900

|

250

|

150

|

|

1000

|

250

|

150

|

|

Items

|

Specifications

|

Test Method

|

|

|

Solid content

|

100%

|

ASTM D 1259

|

|

|

VOCs

|

0%

|

ASTM D 2369

|

|

|

Hardness

|

≥ 70 Shore D

|

ASTM D 2240

|

|

|

Impact strength

|

≥ 8J

|

ASTM D 2794

|

|

|

Volume resistivity

|

≥ 1x1013 Ω.m

|

ASTM D 257

|

|

|

Flexibility, 180º axis bending 102mm mandrel

|

The coating has no cracking and delamination

|

ASTM D 522

|

|

|

Water vapor permeability

|

≤3 mg/24h. cm2

|

ASTM E69

|

|

|

Water absorption

|

≤ 3%

|

ASTM D 570

|

|

|

Cathodic disbonding

|

≤ 10mm

|

ASTM G8

|

|

|

Salt fog resistance, 1000h

|

No change in coating

|

ASTM B117

|

|

|

Resistant to chemical medium corrosion, soak for 30d

|

10% hydrochloric acid, 30%NaOH, 30% sodium chloride, 10% sulfuric acid

|

After soaking 1mm thick sample for 30 days, the change of sample quality and size must be stable and the change is less than 5%

|

ASTM D543

|

Product Display

Product Application

Polyurethane PU coating Ductile Iron Pipes is mainly used in chemical industry, petroleum industry, construction industry, power industry, natural gas industry, shipbuilding industry.

Packing & Delivery

Our Certifications

Get a free quote or free sample

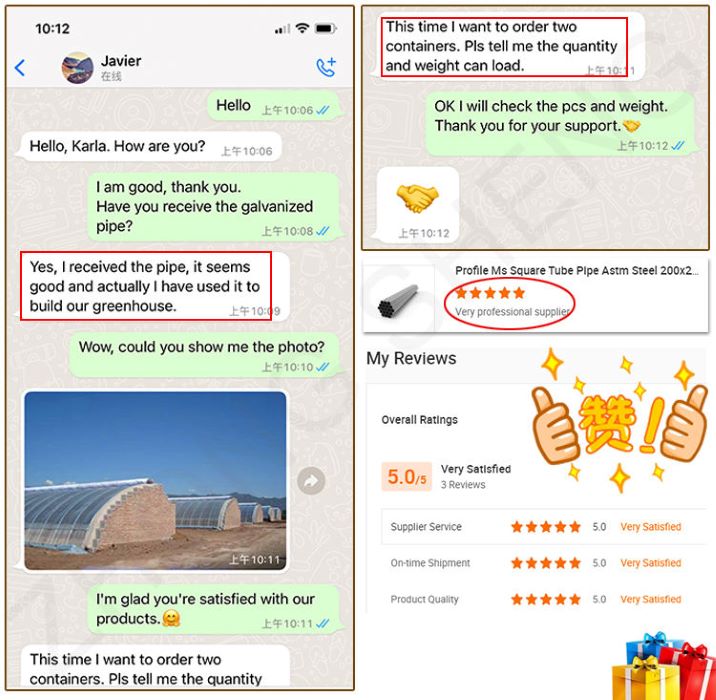

Favorable Comment

FAQ

Q: Are you a manufacturer?

A: Yes , we are a Seamless Steel Tube manufacturer, We have own factory, which is located in Shandong,China. We have a leading power in producing and exporting carbon steel pipe and alloy steel pipe, Stainless Steel Pipe etc. We promise that we are what you are looking for.

Q:Can we visit your factory ?

A:Warmly welcome once we have your schedule we will pick you up .

Q: Do you have quality control?

A: Yes, we can accept BV, SGS third inspection .

Q: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q:How can we get the offer?

A:Please offer the specification of the product,such as material,size,shape,etc.So we can give the best offer.

Q:Can we get the some samples?Any charges?

A:Yes,you can get available samples in our stock.Free for real samples,but customers need to pay the freight cost.

Q: How do you make our business long-term and good relationship ?

A: 1.We keep good quality and competitive price to ensure our customers' benefit.

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.